EPDs don’t contain any proprietary information that manufacturers need to keep within their organization but do disclose the important environmental impact information that is being asked for via the PCR. But, before we get to that, a little housekeeping regarding EPDs: how they’re developed, how long they last, and other background information. We’ll start on Page 2 of almost all EPDs which outlines the second most important set of data in the document.

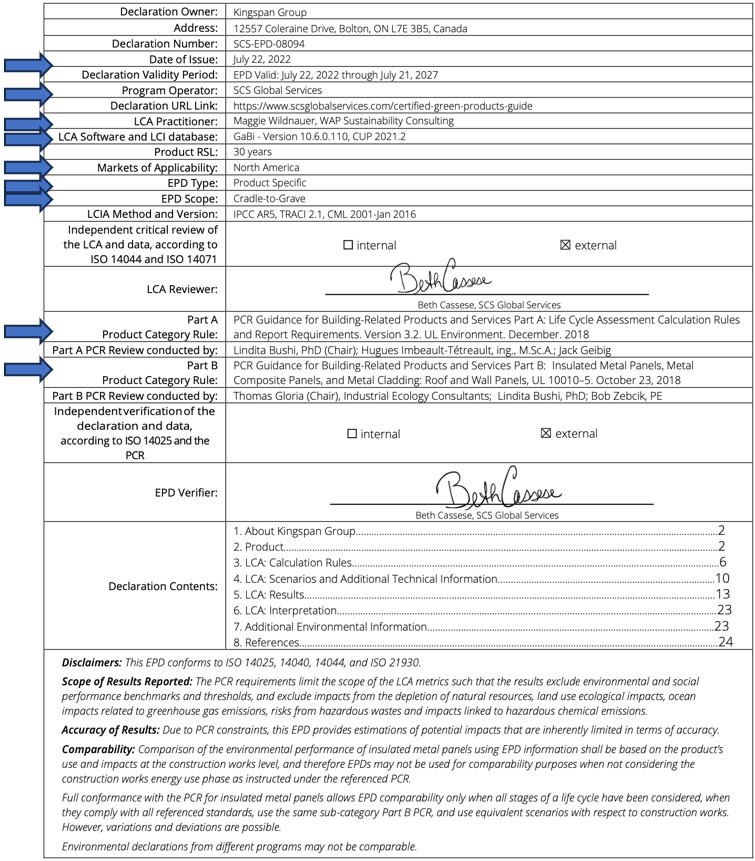

- Date of Issue & Validity Period – this information tells you when the EPD was put into the marketplace. EPDs are typically valid for up to 5 years. This allows you to understand if the EPD that you are looking at when you see it is applicable to the products that are in the marketplace today. Additionally, even though EPDs can be valid for up to 5 years or until the environmental impact of the existing product is different by greater than 10%, many organizations are now updating EPDs much sooner due to their environmental impacts improving through changes in their manufacturing processes and in their supply chain.

- Program Operator – this lets you know who the EPD Program Operator is that verified the EPD. EPD Program Operators should have their EPD Program Instructions publicly available on their website or via email. These instructions detail how the POs are running their program in compliance with ISO requirements.

- LCA Practitioner & LCA Software – this refers to who the life cycle assessment was performed by and what software they utilized to perform the LCA. While LCA providers strive to provide consistent data on all their projects, there are assumptions that the LCA practitioner uses and the software incorporates that can lead to varying levels of uncertainty. Finding that the LCA was performed by a seasoned LCA practitioner using current software versions, and therefore current databases, can lead to great certainty in the data.

- Markets of Applicability – this shows you if the EPD is applicable to the products sold into your market. For manufacturers who make products in multiple regions around the world, typically the life cycle assessment is done on an area of their facilities and then that data is turned into an EPD. This means that the impacts covered in the EPD typically only cover products coming from those facilities where the LCA took place. This allows you to know that the environmental impacts detailed in the EPD are accurate for the product you are purchasing if the locations align.

- EPD Type – there are multiple types of EPDs. An industry-wide EPD comes from a life cycle assessment of a representative sample of the products in a specific market and product type. These can be helpful in terms of setting the average expectations for what the environmental impacts may be from a product type. LCA practitioners and EPD operators perform calculations to ensure that the weighting per products in the market help facilitate the industry average. Next, there are product-specific EPDs, which have traditionally been from LCAs done on products from a group of facilities in a region. These results are then averaged so that any product you are purchasing from that manufacturer in that region has a fair representation of the environmental impacts from the product you are reviewing the EPD for. Finally, there are facility- specific EPDs which are becoming more and more common due to procurement requirements by authorities and architect and designer requests for more specifics on the products they purchase from a specific facility. These EPDs originate from LCAs that are done on a product from a specific facility and typically only represent that one facility’s product.

- EPD Scope – this refers to what stages of the life cycle assessment are covered by the impacts in the environmental product declaration. There are numerous phases of the life cycle of a product – production stage, transport/installation, use stage, and end of life. Each of these phases have multiple substages within them and are represented by colloquialisms “cradle”, “gate”, and “grave”. The most common EPD scope is Cradle to Gate. This represents the environmental impacts from the extraction of raw supplies for a product (Cradle), transport of that to manufacturing, and then manufacturing (Gate – referring to the ‘exit’ from a manufacturers facility). There can also be Cradle to Grave (end of life) and Cradle to Cradle (a circular product). This terminology helps EPD reviewers understand where environmental impacts end in the life cycle of a product for a specific EPD.

- Product Category Rules Followed – these sections detail which product category rules were followed to move the life cycle assessment to an environmental product declaration. The PCR is a set of guidelines, think a standard, which helps determine the data gathering rules and guidance and different scenarios that should be used throughout the LCA. This helps products in the same category to be a bit more comparable if the scopes are the same and similar software was utilized in both LCAs.